Exploring the Charms of Akita with an American Couple〜5

Warning: Undefined array key "file" in /home/xs109313/mina5guide.jp/public_html/wp-includes/media.php on line 1788

Warning: Undefined array key "file" in /home/xs109313/mina5guide.jp/public_html/wp-includes/media.php on line 1788

Tenjyu is one of the few breweries offering tours

There are 37 sake breweries in Akita prefecture.

However few of them offer tours.

Tenjyu is one of the few breweries offering tours.

On this day, the brother of the 7th-generation owner of Tneju gave the tour.

The tour took 40 minutes in Japanese.

You might think that a 40-minute tour is long, but actually there were many interesting new things, so the time flew past.

I translated it into English. Therefore, the brother had to make his explanation shorter than usual. The American couple had visited many wineries. So they could understand the very complicated process to make sake.

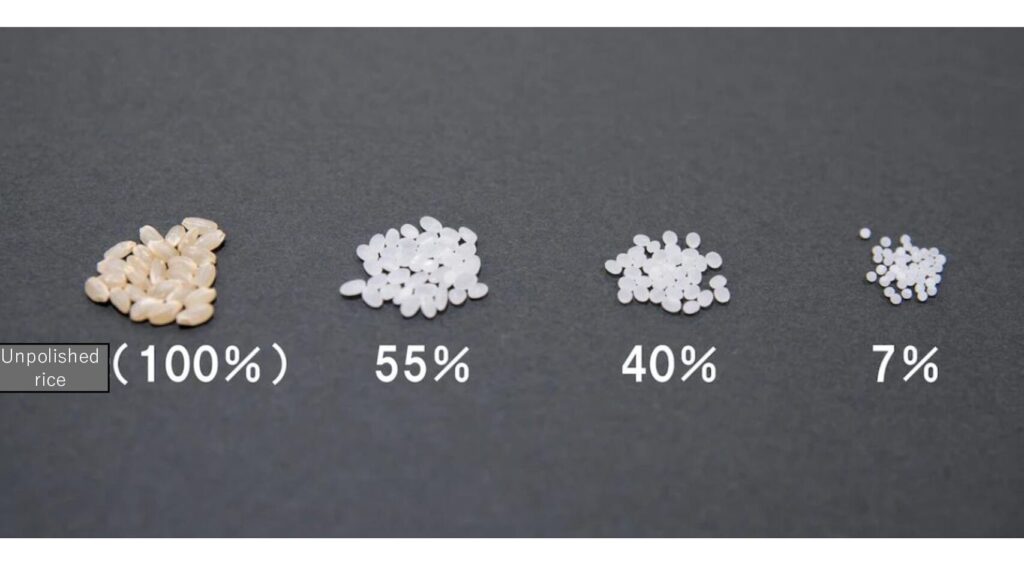

The first part of the process was the rice polishing.

There were many polishing machines, such as a big tank.

For me, one of the most fascinating things I learned was the polishing ratio changes the quality of sake. For example, a polishing ratio of 40 % means 60 % of the rice were polished and 40 % of the rice remains. If the rice polishing ratio is 40% or less, the sake is called “Daiginjo”, which is the highest quality.

The next process is soaking the rice before it is steamed.

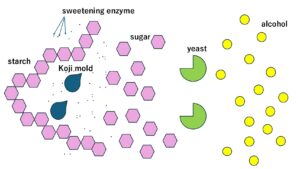

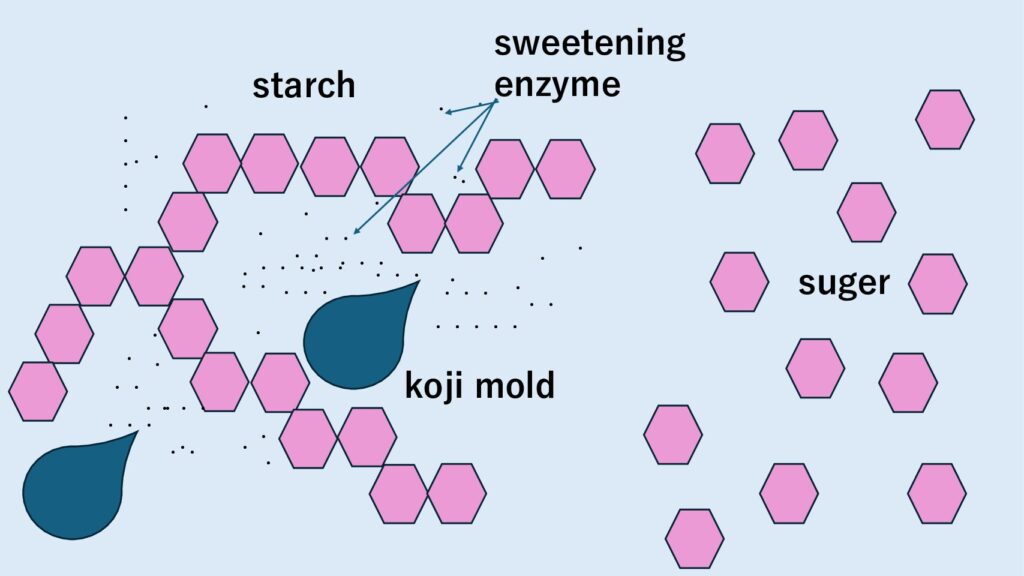

Koji mold is then added to 20 % of the steamed rice.

The koji mold produces many sweetening enzymes, which eat the starch in the rice. The starch is then changed into sugar. And it becomes rice koji.

To be continued